Air Traffic Control Tower System

Aviation Shading System from Reflex-Rol

- Imagine your ATCT goes down to ‘reduced visibility’ status.

- Imagine the reduced landing fees due to ‘reduced visibility’ status.

- Reflex-Rol ‘Aviation’ shading systems can keep your tower functioning even with low angles of sun.

An ATCT (Air Traffic Control Tower) or VCR (Visual Control Room) faces many different environmentally challenging conditions. Of these high on the priority list is VISIBILITY!

In order to afford controllers maximum visibility towers are 360ºglass. Not unlike a greenhouse, with all of the glare, dazzle and solar heat gain associated problems.

Until only a few years ago, shading in ATCT’s was attempted with standard ‘off-the-shelf’ vertical roller blind units adapted with varying degrees of success. Even black-out shades have been used and indeed are still in use in more towers than is safe.

Reflex-Rol, with over a quarter of a century experience in solar, optical and thermal filter technology, have developed the bespoke and acclaimed ‘Aviation’ shading system specifically for vision assistance from and within Air Traffic Control Towers. Supplying optimum levels of external ‘outside’ vision, whilst removing reflections and glare ‘inside’.

A successful shading system for ATCT’s must comprise all of 4 core elements:

- A hight performance solar filter delivering the required optical and thermal properties.

- A hardware system capable of putting the filter int the right place, and keeping it there.

- Ergonomic and reliable controls ensuring ease of adjustment to accommodate the passage of the Sun and the varying levels of light delivered according to season and weather.

- Experienced site assessment, Installation skills and after-sales service.

Film for Windows

Controllers require clear and unencumbered vision through 360º, in all light levels. with ATCT’s generally operating between the hours of 05.00 and 23.00, means whatever the latitude, combating the rising and setting sun every day. With runaways often running East/West the problem is obvious.

Experience of Air Traffic Control Tower installations going back over 15 years now leads us in the great majority of cases (see appendix of installation) to the specification and installation of the Reflex-Rol ‘Aviation’ AR760 and AR762 filter reflectors.

The AR760 and AR762 filter reflectors are manufactured as 1830mm wide sheets. However, windows larger than 1830mm wide and 1830 high are still not a problem. Ultrasonically welded sheets can make up very large shades. (Heathrow ATCT units are 2000mm wide x 5800mm high). The only result is a very narrow dark horizontal line which can be positioned to accommodate the controllers in the tower (depending on ‘line of sight’). If you can provide us with the glass specification for your existing or proposed towers, we can calculate the specific data for your tower.

Window Shape

The inclination of the great majority of air traffic control tower window dictates that the windows are trapezoidal in shape, that the filter reflector is cut very precisely. Our CNC controlled Laser cutter ensures the maximum possible accuracy. However the Laser is only as precise as the information put in. For this reason we at Reflex-Rol UK always insist on a site visit and the measurement of the installed windows prior to manufacture of the shadings system. It is this ensured good fit that delivers performance.

Blind Hardware

A 1st Class filter reflector alone does not guarantee a perfect shading system. Much will depend on the hardware system. The barrel or tube to which the reflector is mounted needs to be of high enough quality not to flex. A low quality aluminium or steel tube at 2 to 3 metres wide can flex up to 5 or 6 mm. The distortion this can cause to the ‘flatness’ of the filter having disastrous affects on both the appearance of and the visibility through the reflector. Our tubes are precision made and machined in Switzerland guaranteeing the absolute minimum amount of deflection.

The ‘housing’ or cassette inside which the entire shade and operating mechanism is mounted five additional rigidity to the whole assembly. Aesthetically neat in an anodised aluminium finish as standard these cassettes can be powder coated to any RAL colour to match immediate surroundings, making for a particularly discrete installation.

Apart from the tube/barrel another critical part to ensure the perfect setup, is the bottom bar/side guide interface. It is of paramount importance that the filter reflector is taut, flat and parallel to the glass (avoiding possible vision distortion). A typical ATCT window is inclined outwards at between 10 and 16º, keeping the filter parallel to this requires the support and guidance of side guides, we use stainless steel wires which run from the headbox, through the bottom bar to anchor points at the base of/below the window. But the bottom bar can only be as wide as the narrowest part of the window, yet must guide and support the filter at any height . The bottom bar needs to be able to be able to expand and contract.

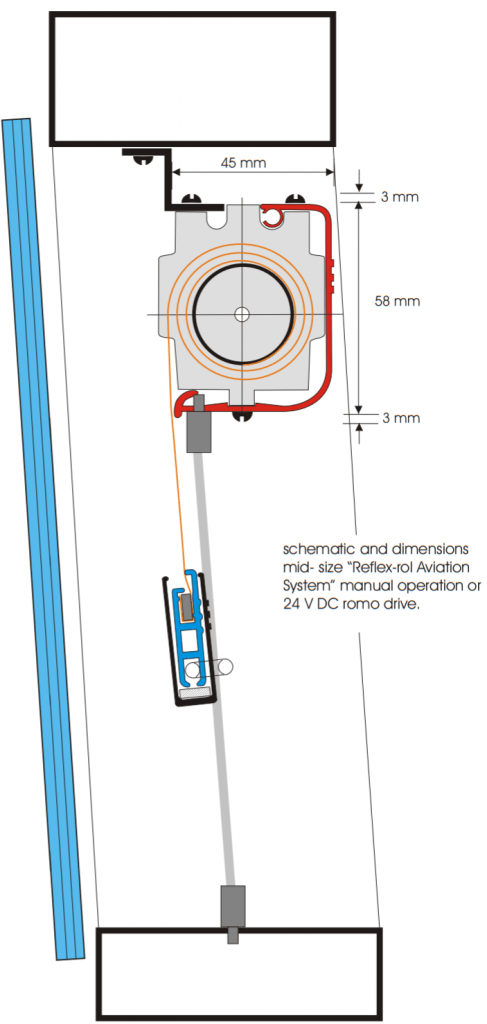

The weight of this bar is precisely calculated, made and tested (see diagram). Into it are mounted purpose designed and engineered, telescopic ‘sliders’ that link to the stainless steel guide wires. When the filter reflector opens/goes up, the telescopic sliders extend slowly, guiding the bottom bar upwards and keeping it clear from the glass. In reverse, when the shade is being lowered the bar compresses. Alignment, weight and tension are key in keeping the filter in place.

Controls

Only with smaller sizes (up to 1500mm wide x 2000mm high) should manual control be considered. Unit sizes over the above dimensions should be motorised. The case for this is easily made. Who and how the shading are used cannot be controlled and, as is human nature, as it is not ones own property, the shading systems do tend to have a hard life.

Smaller sized units can cope with that, larger units will break due to uncontrolled ascent or descent. When motorised, the shade unit will always go up and down in a controlled fashion and will therefore last for many years into the future.

When motorised systems are used there are numerous ways in which to control the systems. Each unit it is own wall/desk mounted switch or a group of 2,3,4 or more units per switch. Radio-remote controls are an option or touch screen operation.

Depending on the sizes of the units we either use 230/240V motors or 24V Agero HD motors.

Whether 230/240V or 24V, these motors are quiet and highly reliable.

Installation

Where possible we prefer to install the systems ourselves. Is this is further afield, outside Europe for example, we send our engineer out to supervise the installation by local labour, usually Airport Engineering Staff. On site training is then given at the same time ensuring a quick response by local staff in the unlikely case of a breakdown.

Spare Parts / Spare Units

Normally most towers have common sized windows in the cab. This means that perhaps one or two complete spare units can be kept in store for a quick change over if needed. A not unknown cause of damage is the window cleaner.

The Replex-Rol ‘Aviation’ shadings system has been designed and is manufactured to exacting standards for it to perform to specification and above all in all climatic conditions. Although most towers benefit from air conditioning, it can still be quite hot in the very top of the cab. With installations on most continents we can safety claim a very high dependability due to precision design, proper specification of materials, and highly skilled workforce in both the assembly and installation process.